How Jeven is leveraging Fidelix’s FX-SC unit to deliver innovative grease filtration solutions

Jeven Oy is a Finnish company that specialises in the design, manufacturing, and distribution of professional kitchen ventilation systems. Founded in 1989, Jeven has become a leading supplier of industrial kitchen ventilation products in the Nordic region, with a strong presence in the Finnish and Swedish markets. Since 2019, Jeven has been part of the Absolent Air Care group.

The company’s product range includes professional kitchen hoods, high-quality grease filtration solutions, and roof hoods for exhaust and inlet air and dampers. Jeven’s products are designed to reduce energy consumption and minimise their impact on the environment while providing superior indoor air quality and comfort.

Fidelix improves buildings and wellbeing

Fidelix Oy is a Finnish company that specialises in building automation systems. Established in 2002, the company has developed a smart, reliable, and widely compatible building automation system that provides customers with better indoor climates, lower energy consumption, and reduced maintenance costs.

Fidelix’s products are developed, tested, and operate in demanding and extreme climate conditions in the Nordics every day, and help to boost the wellbeing of over a million people.

Fidelix is a subsidiary of Assemblin Group, an end-to-end installation and service partner with operations in Sweden, Norway, and Finland. Assemblin designs, instals, and maintains technical systems for the air, water, and energy industries with the vision of creating smart and sustainable installation solutions that make buildings work and people feel comfortable.

The challenge: recovering heat from exhaust systems with filtration

The recovery of heat from kitchen exhaust systems has become more common in recent years due to the increasing focus on sustainability and energy efficiency. Recovering this heat can significantly reduce energy costs and carbon emissions. One of the key challenges of recovering heat from kitchen exhaust systems is the presence of grease, which can clog heat exchangers and reduce efficiency.

In the past, the primary method of removing grease from kitchen exhausts was with baffle filters, which are physical barriers that trap grease particles as they pass through the filter. However, as energy efficiency requirements have become more stringent, hood manufacturers have responded by developing more efficient grease filters that can filter even gaseous grease. These filters use a combination of physical and chemical filtration to remove grease particles and prevent them from entering the heat recovery system.

While there has been a healthy supply of solutions aimed at recovering heat, these solutions produce ozone, a molecule that can be an effective air purifier, but can also be harmful to humans and animals if present in high concentrations. There are even cases where grease filtration is based on the effect of ozone. In these methods, ozone is produced by ozone generators or UV lamps.

Jeven’s UV-Turbo: superior grease filtration and air disinfection

Jeven’s filtration solution UV-Turbo is the only solution on the market that doesn’t produce ozone. UV-Turbo grease filters are equipped with a UV lamp that produces UVC radiation at a wavelength of 254 nm and no ozone. UV radiation with a wavelength of 254 nm has been found to be the most effective in destroying viruses, bacteria, yeast, and spores.

Professional kitchens range from those primarily focused on heating pre-made meals or basic food preparation to high-output restaurant kitchens that require heavy-duty equipment to prepare large quantities of food. There are many types in between, where food is prepared with lighter equipment than in restaurants, such as those in schools, nursing homes, and catering centres.

In these types of kitchens, grease filters with UV and ozone technology are often ‘overdimensioned’ and end up unnecessarily increasing investment and operating costs. On the other hand, the use of traditional grease separators in these locations would prevent the full effectiveness of heat recovery.

Jeven is the only manufacturer that offers the TurboSwing grease filter, which enables the use of modern low-temperature oxidation (LTO) devices without UV or ozone technology, thanks to its grease filtration efficiency. So, for these challenging control needs, Jeven chose Fidelix to be its system provider.

The control logic of the Jeven UV Turbo Hood is designed to be user-friendly and intuitive, with simple controls and clear feedback. By combining UVC light disinfection with adjustable airflow and filter maintenance alerts, Jeven Turbo hoods provide a comprehensive solution for improving air quality and the spread of harmful bacteria and viruses in the kitchen and the exhaust air duct.

The solution: control and monitoring made simple with Fidelix’s FX-SC unit

Jeven uses Fidelix’s FX-SC unit to control and monitor its grease filters and other devices. Before handing FX-SC units to Jeven, Fidelix pre-programmes them with TurboSwing device information such as motor speed and duration and UV light intensity and duration.

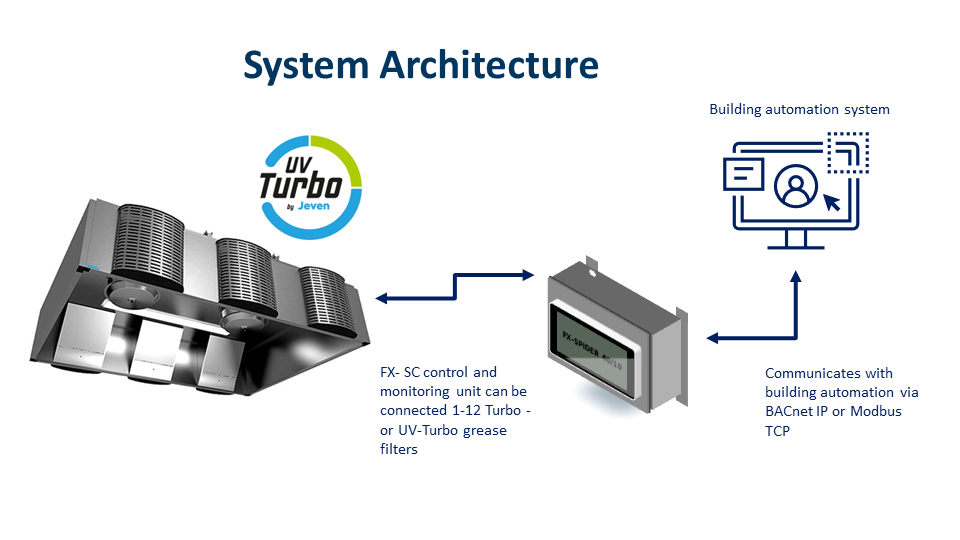

The FX-SC unit is intelligent and easy-to-use, designed to connect to anywhere from one to 12 Turbo or UV-Turbo grease filters. It can operate locally via touchscreen and can easily communicate with building automation via BACnet IP or Modbus TCP protocol.

In addition, the FX-SC unit notifies users of the manufacturer’s recommended time for cleaning grease separators. Users can adjust motor speed and set their own reminder for cleaning the grease separators within a selected time frame.

The FX-SC unit is designed to simplify the control and monitoring of hoods, enabling easy integration with building automation systems. Its pre-programmed settings and reminder features ensure that hoods operate efficiently and effectively, while also maintaining compliance with manufacturer recommendations for maintenance.

The Jeven UV-Turbo is a grease filter whose excellent filtration performance keeps ventilation ducts clean, even from the smallest particles of impurities and gaseous grease. Its use of UVC light disinfects exhaust air and duct surfaces, which prevents the growth of harmful bacteria and viruses, and also reduces odours.

Together, the UV-Turbo and Fidelix’s FX-SC unit makes it easier for Jeven to control and monitor their hoods, and help enable Jeven to offer a comprehensive solution for energy efficient grease filtration and air disinfection.